Our products serve as essential premium ingredients for various industries like extruded snacks, cereals, breweries, bakeries, and pet foods, among others. Driven by our culture of constant innovation and the spirit of reinventing ourselves, we’ve expanded into the clean energy sector, aiming to revolutionize possibilities and drive transformative change for a sustainable future. Our commitment to pushing boundaries and redefining industry standards sets us apart in the grain milling landscape.

Transforming grains to sustain people, nation and the planet

Corn Products

Rice Products

Ethanol

DDGS

CO2

Production Process

for Corn Products

Kernel Journey

Thru Stock Journey

Tail Stock Journey

Production Process

for Rice Products

Production Process

for Biofuel Division

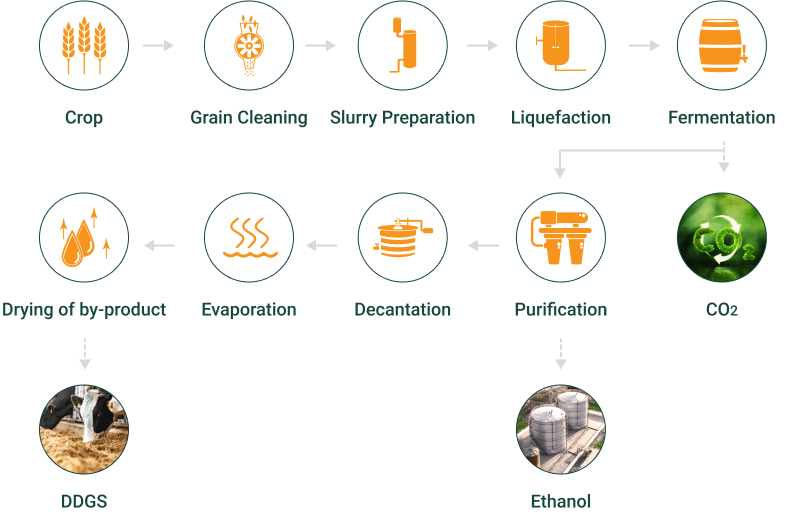

GrainSpan employs an advanced distillation system at the ethanol plant that optimizes grain-to-ethanol conversion with highest quality output. There is a rigorous quality control mechanism set-up to ensure consistent and reliable supply of top-tier ethanol.

Production Process

for Biofuel

GrainSpan employs an advanced distillation system at the ethanol plant that optimizes grain-to-ethanol conversion with highest quality output. There is a rigorous quality control mechanism set-up to ensure consistent and reliable supply of top-tier ethanol.

Production Process

for DDGS

DDGS is a by-product of the rice-based and corn-based ethanol production. It is obtained using the same advanced distillation system and quality control mechanism that are used in the production of ethanol. However, it involves the additional step of drying the by-product to obtain DDGS.

Production Process

for CO2

Corn and rice milling processes release significant amounts of CO2 as a by-product. Instead of releasing this CO2 into the atmosphere, we capture and store it using advanced technology. This capture-and-storage process reduces our environmental impact apart from supporting a circular economy.