India’s transition towards clean, domestically produced energy has placed ethanol and biofuels at the core of national policy. As demand for renewable fuel rises and industries shift toward low-carbon solutions, ethanol manufacturing companies in India have become central players in a rapidly growing sector. Grainspan stands among the new-generation biofuel producers in India, delivering high-purity ethanol and industrial-grade carbon dioxide (CO₂) through sustainable, grain-based production systems that align with the Government of India’s long-term energy vision.

This guide explores the ethanol manufacturing process, the E20 blending programme, industrial applications, CO₂ production potential and the future of India’s green energy landscape.

Overview of Ethanol Manufacturing in India

Ethanol production in India has expanded dramatically in the past decade, driven by strategic policy incentives and the need to reduce fossil-fuel dependence. With the launch of the Ethanol Blended Petrol (EBP) program, India has emerged as one of the world’s fastest-growing ethanol markets.

At its core, the industry is supported by two major feedstock pathways:

- Grain-based ethanol manufacturing (from corn or broken rice)

- Molasses-based ethanol production (from the sugar industry)

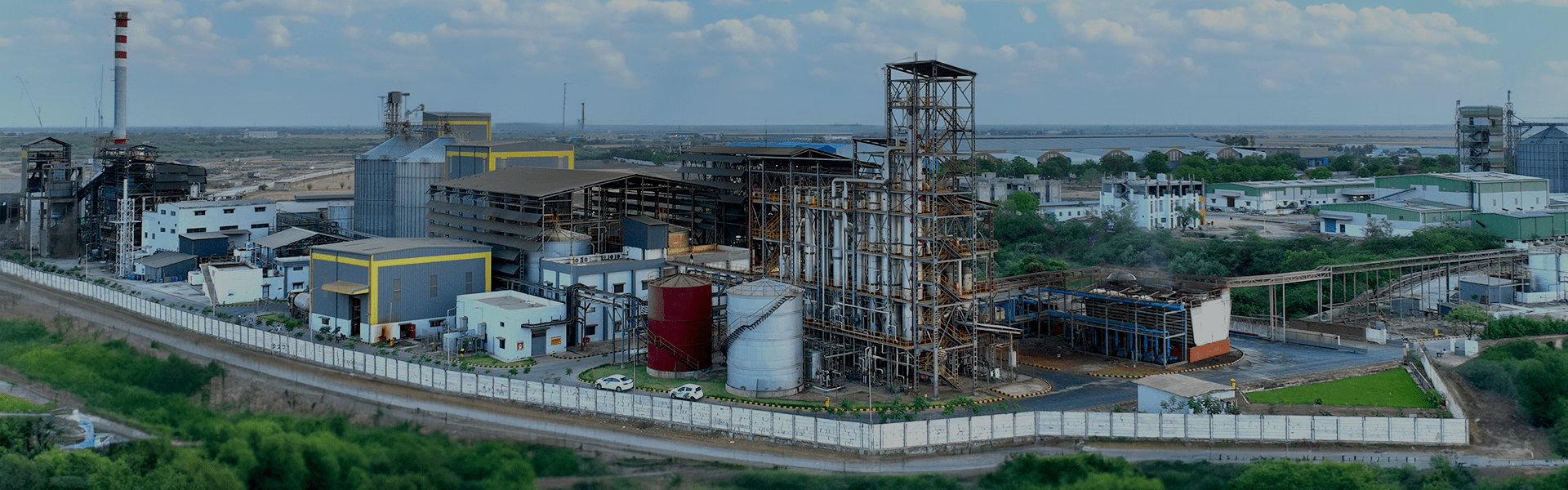

Among these, grain-based units – such as Grainspan’s high-capacity milling and fermentation facilities – offer consistent supply, stable quality, and scalability, making them vital contributors to India’s E20 blending targets.

As a result, the country has witnessed a surge in ethanol manufacturers in India, with large, automated, environmentally conscious plants forming the backbone of national biofuel capacity.

Ethanol Production Process

Ethanol production begins with converting starch-rich grains into fermentable sugars. The process typically involves:

1. Milling & Liquefaction

Grains such as maize or rice are cleaned, milled, and converted into a slurry. Enzymatic liquefaction breaks starch into simpler carbohydrates for fermentation.

2. Fermentation

Specialised yeast strains convert sugars into ethanol. Grainspan’s controlled fermentation systems ensure optimal conversion efficiency and consistent output quality.

3. Distillation & Dehydration

Crude ethanol is purified through multi-stage distillation and molecular sieving to achieve 99.9% fuel-grade purity – the benchmark for India’s fuel blending needs.

4. Co-Product Recovery

Modern plants now run on a circular economy model, generating high-value co-products:

- DDGS (Dried Distillers’ Grains with Solubles) – a protein-rich animal feed

- Corn Oil – used in biodiesel and industrial applications

- Raw CO₂ – captured and purified for beverages, dry ice, and food-processing industries

This integrated approach allows biofuel producers India to deliver both sustainability and economic value across multiple sectors.

Role of Biofuel Producers in India

India’s biofuel producers play a crucial role in:

1. Reducing Crude Oil Imports

Ethanol blending has helped India save thousands of crores in foreign exchange by offsetting petrol consumption.

2. Supporting Farmers & Rural Economies

Grain-based plants purchase maize and rice at scale, improving price stability and creating local employment.

3. Enabling Circular Manufacturing

Co-product utilisation ensures near-zero wastage – a hallmark of responsible manufacturing.

4. Advancing Climate Goals

Bioethanol reduces lifecycle greenhouse gas emissions by up to 35-50% compared to petrol, depending on feedstock and plant efficiency.

With large-scale adoption of E20, ethanol manufacturing companies in India will play an even larger role in national carbon-reduction frameworks.

Government Ethanol Blending Programme (EBP)

The EBP programme is India’s flagship initiative for integrating renewable fuels into mainstream mobility. Key milestones include:

- 10% ethanol blending achieved in 2022 – ahead of schedule

- E20 rollout launched in 2023, expanding across multiple states

- National target: 20% blending by 2025-26

Under this programme, oil marketing companies purchase fuel-grade ethanol directly from approved ethanol manufacturers India, ensuring guaranteed market demand and long-term industry stability.

Grainspan’s 350 KLPD grain-based ethanol plant contributes directly to E20 implementation by providing consistent, high-purity ethanol to national fuel networks.

Industrial Uses of Ethanol

While fuel blending remains the largest segment, ethanol is also indispensable to a wide range of industrial applications:

1. Chemicals & Solvents

Used in paints, coatings, adhesives, cleaning formulations, and laboratory applications.

2. Pharmaceuticals

Key solvent for manufacturing medicinal compounds, sanitizers, disinfectants, and drug formulations.

3. FMCG & Beverages

High-purity grades support beverage production, personal care products, and food extracts.

4. Energy & Power

Ethanol is increasingly used in alternative energy systems, micro-turbines, and combustion engines designed for renewable fuels.

A reliable supply from modern ethanol manufacturing companies in India enables industries to maintain purity standards and production consistency.

Carbon Dioxide (CO₂) Production from Ethanol Plants

One of the major advantages of grain-based ethanol units is their ability to supply food-grade and industrial carbon dioxide. During fermentation, CO₂ is released as a natural by-product. Instead of venting this gas, integrated plants like Grainspan capture, purify, and liquefy it for commercial use.

High-purity CO₂ has wide applications:

- Beverage carbonation (soft drinks, packaged beverages)

- Dry ice manufacturing

- Cold-chain logistics & refrigeration

- Welding and fire suppression systems

- Food preservation & modified atmosphere packaging

This makes ethanol plants one of the most efficient CO₂ production companies in the industrial ecosystem.

Market Demand for CO₂ in India

India’s CO₂ demand has expanded significantly in:

1. Beverage Industry

Growth in packaged drinks, breweries, and carbonated beverages drives stable demand for food-grade CO₂.

2. Cold Chain Logistics

As e-commerce and frozen foods grow, dry ice manufacturing has seen double-digit market growth.

3. Welding & Manufacturing

Metal fabrication and engineering industries depend on high-purity industrial CO₂.

4. Pharmaceuticals

Used in extraction, sterilisation, and controlled-environment operations.

Ethanol plants produce consistent CO₂ year-round, making them vital suppliers for industries with continuous demand cycles.

Future Scope of Biofuels & Green Energy

India’s ethanol and biofuel ecosystem is poised for exponential growth driven by:

1. E20 Nationwide Adoption

Government policy ensures long-term viability and expansion of ethanol capacity.

2. Second-Generation Biofuels (2G Ethanol)

Utilisation of agricultural residues and non-food biomass will strengthen India’s renewable energy portfolio.

3. Green Hydrogen Synergy

Bioethanol reforming offers pathways to hydrogen generation – a major future energy pillar.

4. Expanding Industrial CO₂ Market

Growing demand for food-grade and industrial CO₂ offers strong revenue diversification opportunities for ethanol plants.

As one of the leading ethanol manufacturers India, Grainspan continues to expand its grain-based capacity, sustainability measures, and carbon-capture systems to support India’s clean-energy transition.

Conclusion

The evolution of ethanol manufacturing companies in India marks a turning point in the national shift towards renewable, circular, and low-emission energy systems. With technological innovation, sustainable sourcing, high-purity production, and CO₂ capture, Grainspan delivers reliable solutions for fuel blending, industrial applications, and green-energy development.

Call to Action

Request a Quote for Fuel or Industrial Ethanol

Contact Us for CO₂ Supply & Biofuel Collaboration

Bulk Ethanol & Industrial Gas Supply Available