In the competitive world of food manufacturing, the smallest variation in ingredients can have a big impact. For brands that prioritise quality and consistency, working with a dependable supplier is not just a convenience—it’s a necessity. Whether it’s for savoury snacks, cereals, baked goods, animal feed or beverage blends, every batch depends on the predictability and performance of its core ingredients. Among the most widely used inputs across these categories is corn—a versatile grain that shows up as flour, grits, starch, fibers, and more.

As demand for corn-based ingredients continues to rise, so does the pressure on food manufacturers to source from dependable, high-quality suppliers. But with dozens of players in the market, how do you identify the right one?

Here’s what every food manufacturer should look for—and why GrainSpan has emerged as a trusted name in this space.

Why Corn-Based Products Matter So Much in Food Manufacturing

Corn isn’t just one of the most cultivated grains globally—it’s also one of the most flexible. In India, and increasingly across global markets, corn derivatives are used in:

- Snack foods – Corn grits and maize flour are foundational in extruded and fried snacks.

- Breakfast cereals – Flaking grits are often the mainstay of cereals thanks to their texture and mild flavour.

- Baking ingredients – Corn flour and starches offer functional benefits such as improved crumb structure and moisture retention.

- Animal nutrition – Corn derivatives like DDGS (Dried Distillers Grains with Solubles) contribute protein-rich content to livestock feed.

- Beverage and sweetener production – Corn starch plays a role in fermentable sugar production, and corn-based ethanol finds increasing use in beverages and biofuels alike.

This diversity makes corn indispensable. And yet, because it spans so many uses, the quality expectations vary—and not every supplier can keep up with the range.

What Sets a Great Corn Product Supplier Apart

Before partnering with a supplier, food manufacturers should evaluate a few key factors that go beyond just cost or location.

- Consistency in Quality

The best suppliers don’t just promise quality; they standardise it. Look for facilities that have rigorous testing in place at every stage—from raw material intake to final packing. Uniform particle size, moisture control, and microbial safety are just the basics.

- Certifications and Food Safety Compliance

Any supplier serving the food industry must hold relevant certifications. At a minimum, this includes FSSAI, ISO, HACCP, and ideally, BRC or other global standards if exports are involved.

- Range and Customisation

Depending on your product line, you may need fine maize flour one day and coarse corn grits the next. Suppliers that offer tailored granulation, colour, and functional properties give manufacturers a distinct edge.

- Supply Chain Reliability

Having a state-of-the-art plant is only useful if the product reaches you on time. Evaluate the supplier’s logistics network, lead times, and ability to scale in line with your demand.

- Sustainability and Traceability

More brands are asking: Where did this ingredient come from? Ethical sourcing and low-carbon manufacturing aren’t just good practice—they’re fast becoming industry requirements.

GrainSpan: A Partner in Quality Corn Processing

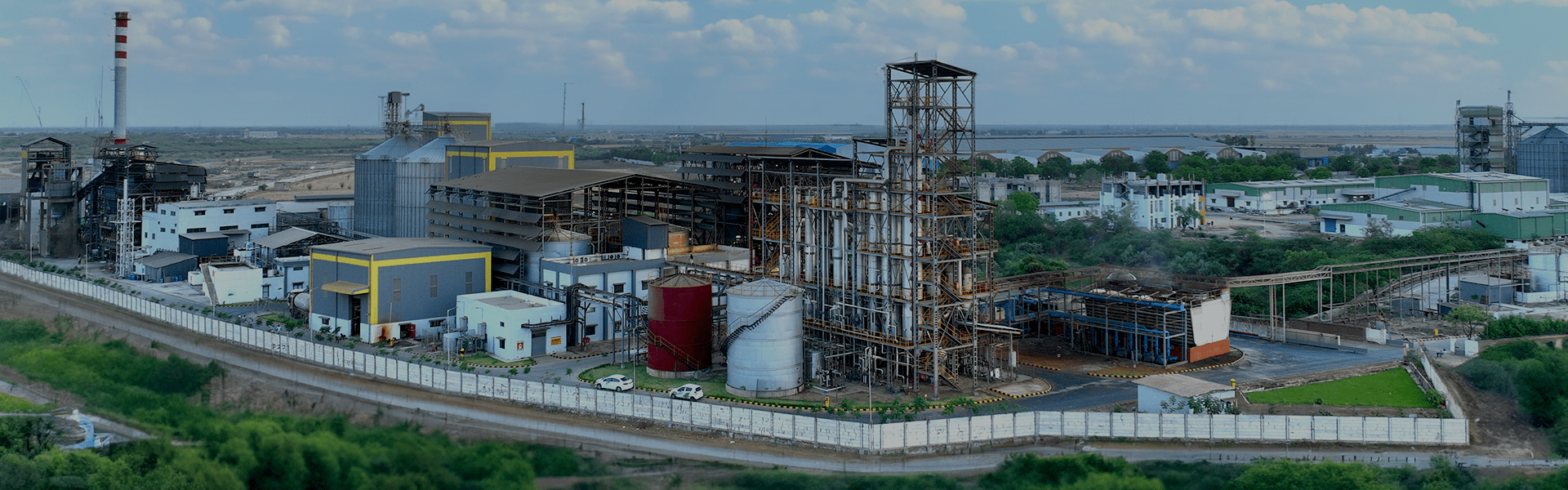

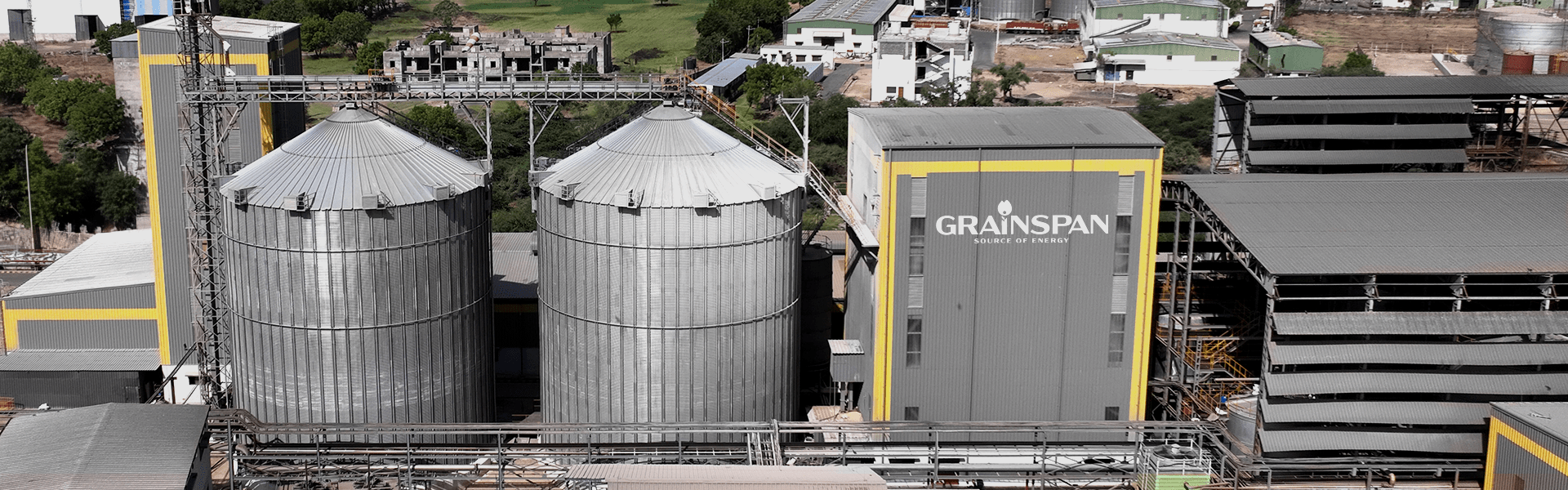

GrainSpan Nutrients has built its reputation by aligning with the precise needs of food manufacturers. Headquartered in Ahmedabad, GrainSpan is redefining how corn is processed and supplied to the food industry. With operations that span both domestic and export markets, the company has built a fully integrated system—from sourcing premium-grade corn to producing refined flours, grits, and fermentation co-products like DDGS.

What sets GrainSpan apart is not just the scale of its infrastructure, but its commitment to tailored solutions and reliable service:

- Advanced Facilities: With precision milling and high-capacity fermentation plants, GrainSpan ensures that every lot—from fine corn flour to coarse grits—is produced with uniformity and strict quality control.

- Customisation Through Collaboration: Instead of pushing generic solutions, the team works closely with manufacturers to meet specific functional needs—be it modifying grind size, adjusting starch levels, or optimising moisture content for a particular recipe.

- Sustainability Built In: GrainSpan takes pride in operating a closed-loop system, converting agricultural byproducts into bioethanol and high-protein animal feed. This not only reduces waste but supports circular economies in agriculture and energy.

- Dependable Logistics: From scalable warehousing to regional distribution hubs, GrainSpan backs its products with a well-managed supply chain. Clients benefit from consistent lead times, real-time delivery updates, and flexibility in order volumes.

In an industry where “almost right” can lead to costly inconsistencies, this kind of control over every stage of production and delivery offers tangible value.

Manufacturers who prioritise ingredient traceability, supplier collaboration, and long-term consistency will be better placed to meet changing consumer expectations.

GrainSpan welcomes partnerships that go beyond transactions. Whether you’re a new player or an established manufacturer seeking a more dependable corn ingredient partner, we’re here to support your growth.

Let’s work together.

Connect with us for product samples or bulk supply inquiries.