Where sustainability meets precision in every captured molecule

When people think of ethanol, they rarely consider what happens to everything else left behind in the process. At GrainSpan, that “everything else” includes a resource we don’t let go to waste: carbon dioxide. Every bubble that escapes during fermentation tells a story—of careful capture, rigorous testing, and a second life in industries that rely on purity and consistency.

A Hidden Essential in Our Daily Lives

Carbon dioxide is more than just a gas. It’s what gives soft drinks their fizz, helps preserve food in packaging, and keeps systems cool in industries far beyond food and beverage. But not all CO₂ is suitable for human contact. To make it to your favourite beverage or the cold chain that keeps your produce fresh, it has to meet incredibly strict quality standards. That’s where GrainSpan steps in.

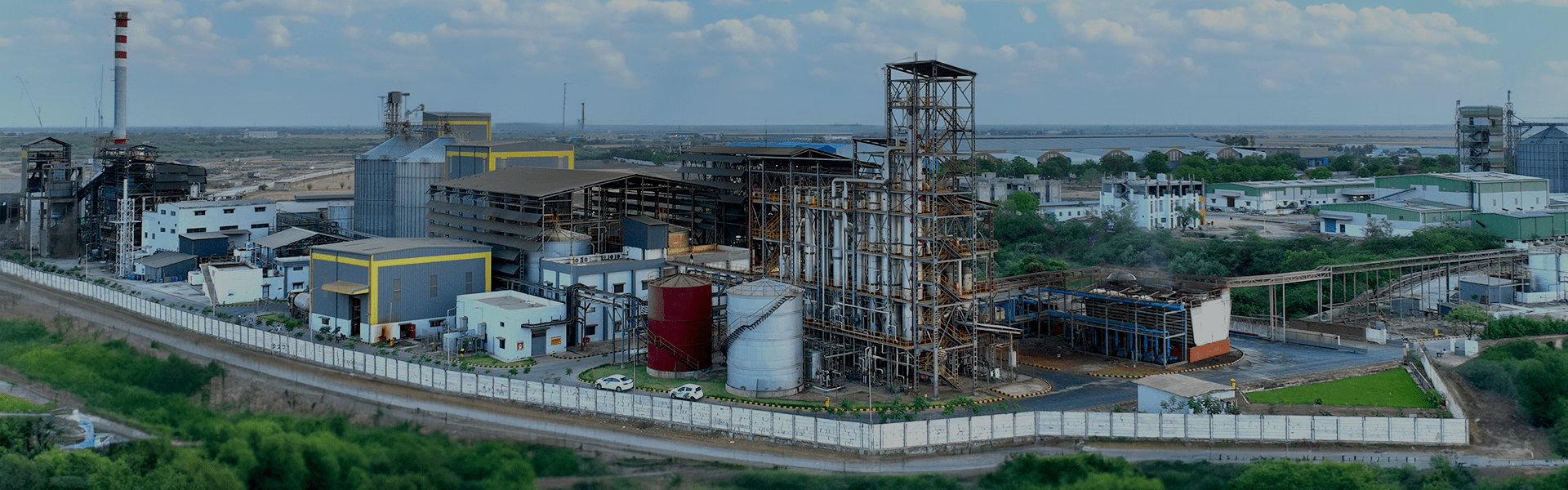

Our process starts at the source—grain-based ethanol fermentation. As maize or rice breaks down into energy, it naturally releases CO₂. Instead of letting this escape into the atmosphere, we recover it right from the heart of the process.

From Emission to Ingredient: What Happens in Between

Once captured, the CO₂ undergoes a multi-step transformation. It’s not just cleaned—it’s refined. First, we compress and cool it to eliminate moisture. Then, we remove any trace impurities, from sulphur compounds to odour-causing residues. Dehydration follows, along with a final polishing phase to meet food-grade thresholds.

The result? A consistent, high-purity output that’s ready for sensitive applications—from carbonated beverages to precise industrial systems.

Tested, Trusted, and Traceable

Every batch of CO₂ we produce is held to a standard that goes beyond routine checks. In-house testing looks at purity levels, moisture content, microbial presence, and even sensory factors like smell and taste. What leaves our facility is compliant with food and beverage safety regulations and supported with traceable batch data.

Our customers—whether they’re bottling drinks or packaging perishables—depend on that consistency. And for us, it’s non-negotiable.

A Model Rooted in Circular Value

What sets our approach apart is how seamlessly this CO₂ stream fits into our larger vision of integrated grain-based processing. Ethanol is our primary product, but the value doesn’t stop there. By capturing CO₂ and putting it to use, we not only avoid unnecessary emissions—we create a valuable input that serves multiple industries. It’s part of a closed-loop, low-waste model that defines how we operate.

This mindset reflects a shift in manufacturing thinking. Every by-product has potential; it just needs the right infrastructure to unlock it. That’s the promise of our CO₂ program.

Where It Goes—and Why It Matters

GrainSpan’s CO₂ reaches a wide network. From beverage plants to agriculture facilities, our gas plays a role in:

- Carbonating soft drinks and sparkling water

- Preserving foods through modified-atmosphere packaging

- Supporting industrial welding and fire suppression systems

- Enabling controlled greenhouse environments

- Maintaining cold chains in logistics and retail

Each of these relies on high-purity, food-grade CO₂—and on suppliers who can deliver it reliably, year-round.

Raising the Bar for Responsibility

We don’t just meet requirements—we build on them. At a time when emissions are under scrutiny and global energy needs are evolving, our ability to transform waste gas into a functional product speaks volumes about what modern manufacturing can—and should—look like.

It’s not only about what we produce, but how responsibly we manage every step. For us, innovation isn’t separate from accountability; it’s built into the process.

The GrainSpan Perspective

From corn to carbonation, our process ensures that no resource is wasted and no quality is compromised. The CO₂ we deliver is part of a bigger picture—where every grain processed brings value not only to our customers, but to the broader ecosystem we serve.

If you’re in the market for high-purity CO₂ for beverage, food-grade, or industrial use, GrainSpan is ready to support your needs—with consistency, safety, and sustainability at the core.