In today’s fast-evolving manufacturing landscape, the role of grain-based ingredients is undergoing a quiet but powerful transformation. No longer just raw materials, these ingredients are becoming critical tools — shaping how food and feed products are made, how they perform, and how consumers perceive them.

Whether it’s a corn grit for cereal or a flour blend used in baked snacks, manufacturers now expect more: consistent performance, custom processing, and ingredients that align with their quality standards and innovation goals.

Understanding What’s Driving the Shift

A lot has changed in the last decade. With consumer demand rising for healthier, cleaner, and more transparent products, manufacturers are adapting. They’re choosing inputs not just for what they are, but for what they can do.

Corn flour and corn grit, for example, are no longer just bulk fillers. They now serve specific functions — affecting product texture, shelf life, and even production speed. In the feed industry too, precision matters. Nutritional consistency, digestibility, and formulation flexibility are critical when producing animal feed at scale.

As expectations rise, so does the need for suppliers who can deliver on those demands — consistently and with technical know-how.

How Corn Milling Is Evolving

Modern corn milling is about more than size and yield. It’s about control.

Milling companies are now investing in technology that allows for precise adjustments in granulation, starch levels, moisture content, and temperature stability. These factors have a direct impact on how ingredients behave during processing — whether it’s extrusion, baking, or blending.

For example, a corn grit used for brewing has entirely different specs than one meant for snack pellets. The same applies to flours intended for instant mixes versus ready-to-cook products. Small variations can affect everything from processing efficiency to final product appearance.

That’s why more manufacturers are choosing custom grain processing solutions — not just for quality, but to improve line productivity and reduce waste.

When Customisation Makes the Difference

It’s easy to underestimate the impact of getting an ingredient “just right.” But anyone working on a production line knows the cost of an inconsistent input — machine downtime, reformulations, or worse, product rejection.

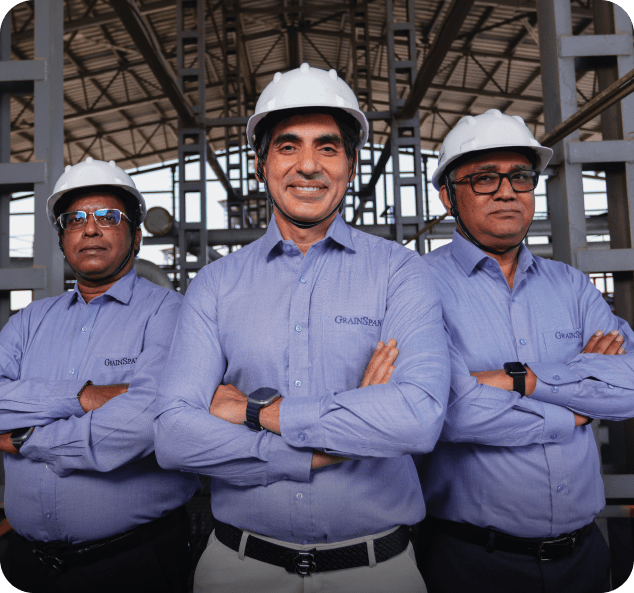

At GrainSpan, our approach is to work alongside manufacturers to understand exactly what their process needs. Whether it’s a specific moisture threshold or a custom particle size, our team tailors each ingredient to suit the end-use — right from the first batch.

This flexibility is especially valuable in industries like snack foods, pet food, and livestock feed, where consistency and performance must align with safety, nutrition, and cost-efficiency.

Why Clean, Efficient Supply Chains Now Matter More Than Ever

Modern brands care about where their ingredients come from, how they’re processed, and whether the sourcing is ethical and efficient. They want traceability. They want transparency. And they want confidence that the product will be the same — every time.

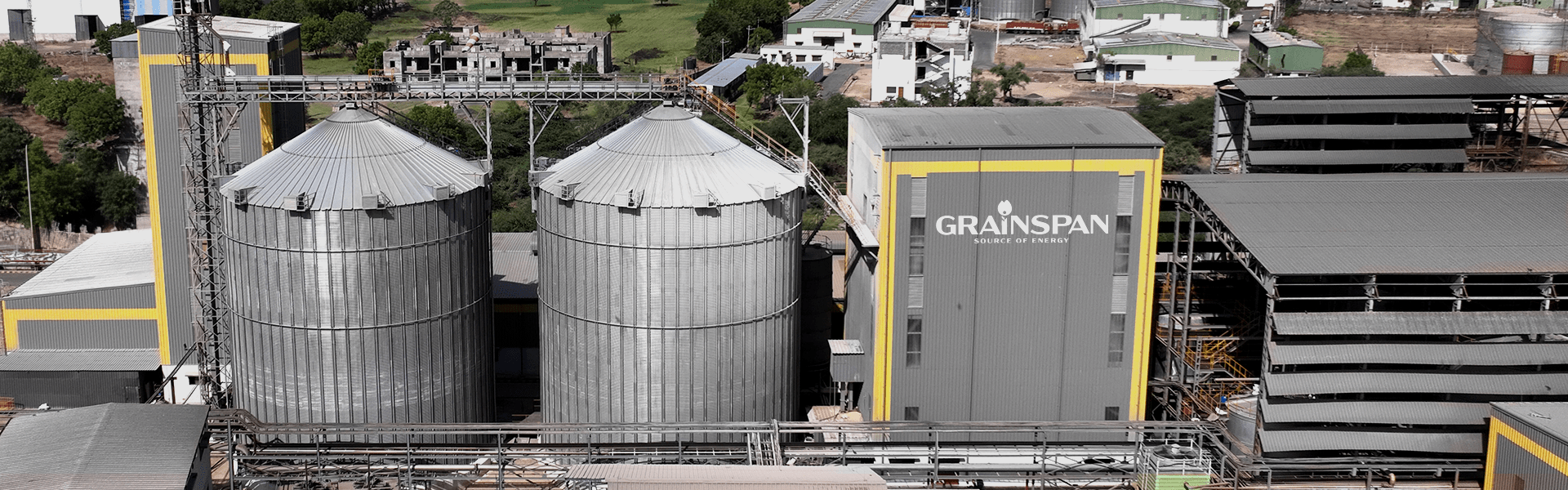

To meet this need, GrainSpan has developed a vertically integrated supply chain that supports everything from raw maize procurement to on-time delivery of finished products. Dedicated storage, identity-preserved raw material segregation, and robust QA protocols ensure minimal cross-contamination and maximum consistency.

This is more than logistics — it’s assurance.

Manufacturing With Sustainability in Mind

Today, sustainability isn’t a buzzword. It’s a requirement. Manufacturers are under pressure to reduce waste, lower emissions, and move towards circularity.

GrainSpan incorporates sustainability at every level of our process. Our corn and rice milling operations are built to reduce waste, reclaim value, and create multiple streams of impact. The bran and fibre that many discard? We convert into DDGS — high-protein feed used across the livestock sector. Fermentation residues become ethanol — a cleaner, domestic energy source. CO₂ generated in the process is captured and supplied to beverage companies and industrial users, closing the loop.

By treating every by-product as a resource, we offer our clients an ingredient source that supports both performance and planet.

The GrainSpan Approach

We don’t just sell corn flour or maize grit — we engineer ingredient solutions that help manufacturers meet their production, nutritional, and sustainability goals. Our facilities, spread across strategic locations in India, are equipped to meet high-volume demands while maintaining quality standards.

With deep expertise in milling, fermentation, and custom processing, we support industries ranging from cereals and baked snacks to brewing and animal nutrition.

And we’re just getting started.

Final Word

Manufacturing is evolving — and so are its ingredients. As the demand for function-driven, clean, and scalable grain inputs grows, the need for reliable partners who understand both application and impact becomes critical.

GrainSpan is proud to be at that intersection.

If you’re exploring high-quality, customisable corn flour or maize grit for your operations, or seeking a more sustainable and technically aligned supplier — let’s talk. Our team is ready to support your growth.