As global demand for processed rice products continues to grow, professional rice milling services have become a critical link between agricultural production and international food markets. From bulk rice supply to food-grade rice flour exports, modern rice milling today is no longer limited to basic processing-it is a highly specialised, technology-driven operation that ensures quality, consistency, and export compliance.

For importers, food manufacturers, FMCG brands, and distributors, choosing the right rice milling and export partner directly impacts product quality, regulatory acceptance, and supply reliability. This comprehensive guide explains how commercial rice milling works, why professional exporters matter, and how trusted rice product suppliers support global markets.

What Are Rice Milling Services?

Rice milling services refer to the industrial process of converting raw paddy into consumable and market-ready rice products through a series of controlled mechanical and quality-focused steps. Modern commercial rice milling is designed to maximise yield, preserve grain integrity, and meet food safety standards required for domestic and export markets.

The Rice Milling Process Explained

A professional rice milling process typically includes:

- Cleaning: Removal of stones, dust, and foreign matter

- Husking: Separation of husk from paddy

- Whitening: Removal of bran layers

- Polishing: Improving grain appearance and texture

- Grading: Sorting rice based on size and quality

- Quality Control: Moisture, broken percentage, and purity checks

Advanced milling technology ensures minimal grain breakage, consistent output, and optimal recovery-factors that are essential for export-grade rice.

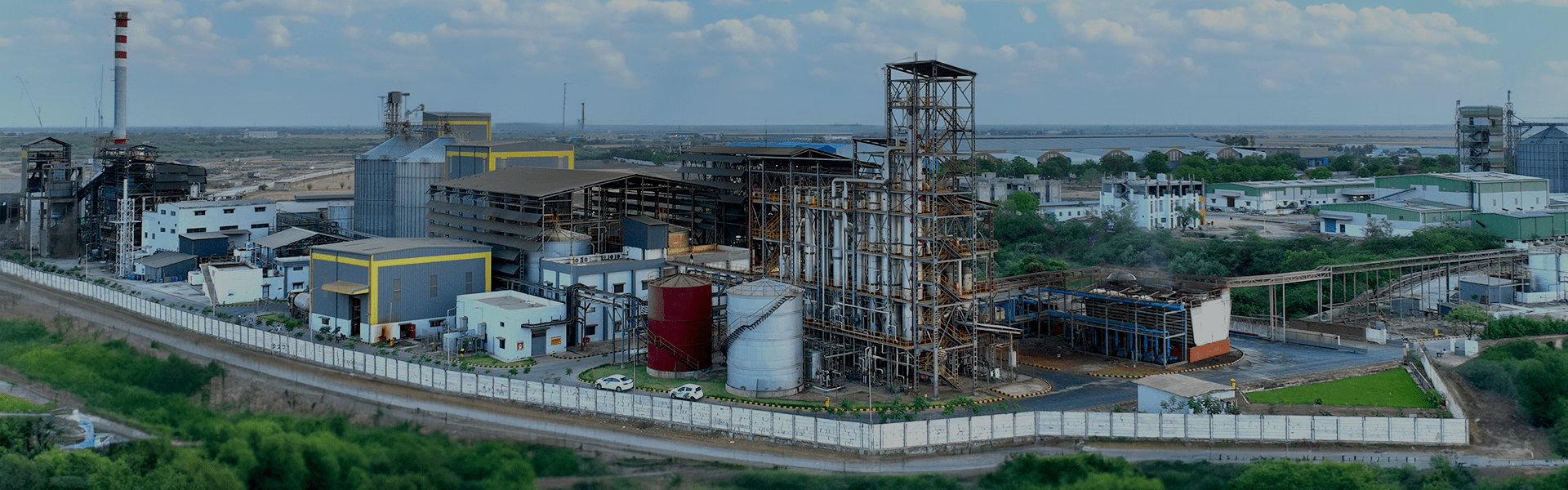

Modern rice mills also integrate automation and controlled environments to maintain hygiene and processing efficiency across large volumes.

Why Choose Professional Rice Milling Exporters

Working with experienced rice milling exporters offers clear advantages over fragmented or non-specialised processors. Export-focused mills are designed to meet international quality, packaging, and documentation standards.

Export-Grade Milling Standards

Professional exporters maintain tight control over:

- Grain uniformity

- Moisture content

- Broken rice percentages

- Visual and physical quality

These parameters are essential for meeting buyer specifications across global markets.

Compliance with International Regulations

Reliable rice export services ensure compliance with:

- Import country food safety regulations

- Phytosanitary requirements

- Packaging and labelling norms

- Traceability and batch documentation

This reduces risk at destination ports and ensures smoother customs clearance.

Packaging, Storage & Bulk Shipment Handling

Export-oriented rice mills offer flexible packaging options such as:

- 25 kg / 50 kg bags

- Jumbo bags

- Containerised bulk shipments

Proper storage and inventory management ensure product integrity until final delivery.

Trusted Rice Product Suppliers for Global Markets

Leading rice product suppliers serve a wide range of buyers-from wholesale importers to food manufacturers and retail brands. Consistency, sourcing reliability, and product diversification are key differentiators in this segment.

Types of Rice Products Supplied

Professional suppliers offer a portfolio of processed rice products, including:

- Raw rice

- Parboiled rice

- Broken rice

- Rice by-products for food and feed applications

Each product type serves different markets and industrial uses, requiring precise processing and grading.

Importance of Consistency & Sourcing

For bulk rice suppliers, uniformity across shipments is essential. Buyers expect the same grain characteristics across repeat orders, making sourcing discipline and quality controls critical.

Private Labelling & Custom Orders

Many global buyers prefer private-label or customised product specifications. Established rice product suppliers support:

- Custom grain specifications

- Brand-specific packaging

- Long-term contract supply

Rice Flour Exporters – Processing & Applications

The demand for rice flour has expanded significantly due to its versatility and suitability for specialised food applications. Reputed rice flour exporters focus on producing consistent, fine-grade flour that meets both food and industrial requirements.

Rice Flour Processing

Food-grade rice flour is produced by finely milling selected rice grains under controlled conditions to achieve:

- Uniform particle size

- Low moisture content

- Neutral flavour and colour

This precision is essential for food manufacturers who rely on functional performance.

Applications of Rice Flour

Rice flour is widely used in:

- Bakery and confectionery products

- Gluten-free food formulations

- Snack coatings and batters

- Industrial food applications

As a naturally gluten-free ingredient, rice flour continues to gain popularity in health-focused and export markets.

Quality Standards & Export Compliance

Professional rice flour suppliers ensure compliance with food safety standards and export certifications, making the product suitable for international distribution.

Global Export Capabilities & Supply Chain Strength

Strong export capability is what separates local processors from global suppliers. Established rice milling exporters invest in logistics and supply-chain infrastructure to support consistent international delivery.

International Shipping & Logistics

Export-ready rice mills coordinate:

- Container planning

- Port handling

- Documentation support

- Delivery timelines

This ensures smooth movement from mill to destination market.

Packaging Formats

Flexible packaging options include:

- Standard bags

- Jumbo bags

- Containerised bulk shipments

Packaging is designed to protect product quality during transit.

Destination Markets & Scalability

Professional exporters support supply to multiple international markets while scaling volumes based on seasonal and contractual demand.

Quality Standards & Certifications

Quality assurance is central to professional rice milling and export operations.

Quality Checks at Every Stage

A certified rice mill implements quality controls during:

- Raw paddy procurement

- Milling and polishing

- Final packaging

Compliance with Food Safety Standards

Export-grade mills follow internationally recognised food safety standards, ensuring products meet buyer and regulatory expectations.

Traceability & Batch Control

Traceability systems allow tracking of each batch from sourcing to shipment, providing transparency and accountability.

How to Choose the Right Rice Milling & Export Partner

Selecting the right partner for rice milling services and exports is a strategic decision.

Key Factors to Evaluate

- Proven experience in commercial rice milling

- Modern infrastructure and processing technology

- Export handling capability

- Quality certifications and compliance systems

Capacity & Technology

High-capacity mills with automated systems ensure consistency, efficiency, and scalability for long-term supply relationships.

Client Support & Export Experience

Reliable partners provide support across specifications, documentation, and logistics-reducing complexity for buyers.

Conclusion – One-Stop Solution for Rice Milling & Exports

Professional rice milling services, supported by reliable rice product suppliers and experienced rice flour exporters, form the backbone of a successful rice export operation. From precision milling and food-grade flour production to bulk exports and global logistics, working with an integrated partner ensures quality, consistency, and long-term reliability.

For businesses seeking a dependable, export-ready solution, choosing the right rice milling and supply partner makes all the difference.

Call to Action

Contact us for bulk rice milling and export inquiries.